Product Description

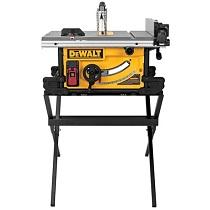

Product Details

- Amazon Sales Rank: #13309 in Home Improvement

- Size: 1

- Brand: DEWALT

- Model: DWE7490X

- Number of items: 1

- Dimensions: 30.25" h x20.38" w x30.75" l,87.50 pounds

Features

- Rack and pinion telescoping fence rails make fence adjustments fast, smooth and accurate

- 28" of rip capacity easily cuts a variety of larger shelving and trim material

- 15 Amp, high-torque motor with the power to cut pressure-treated lumber and hardwoods

- Site - Pro Modular Guarding System allows for tool free adjustments of the guarding components

- Telescoping fence rails retract to create a small, portable package

Customer Reviews

Most helpful customer reviews

14 of 14 people found the following review helpful.![]() The best of many saw designs for the money

The best of many saw designs for the money

By Reluctant Consumer

I am a contractor of 20+ years and had to replace my Makita 2708 after 15+ years of hard use. I was happy with the Makita which I used set up in a Rouseau stand with the Rouseau fence and out-feed table. My indestructible Rouseau stand of 20+ years still works great so I was hoping to find a 10" saw compatible with it. I was looking for a portable saw that would be easy to set up on a job and store in my trailer. Unfortunately the quality 10" saws available now are not compatible with my Rouseau stand and the 2708 is no longer in production. I was going to buy either the Bosch GTS1031 or the Dewalt DW745. I love the design of the Bosch but, after reading the reviews and then going to see one in person, and witnessing myself the play in the arbor, the GTS1031 really is poorly made (uncharacteristic of a Bosch product!). This saw, the DWE7490X, appears to incorporate all the features of the Bosch GTS1031 design (Roll cage, one-handed horizontal carrying/storing, on-board storage) plus some other nice features of the larger portable saws into the best design I have seen so far for carpenters seeking a portable job-site table saw capable of finish-grade work. I'll report back again after using it in the field some.

Things I like about this saw:

1. The rubber feet. I had to transport the saw up a narrow flight of stairs on my first job with this saw and I encountered an unforeseen obstacle in my path. I adjusted to avoid the obstacle and consequently the bottom corner of the saw bumped into the wall. No damage was done because of the large cushioned feet. The rubber feet also serve to protect any surface the saw might be sitting on. They also steady the saw by providing grip while also reducing vibration during use.

2. Rip capacity. 28-1/2"

3. On-board out-of-the-way storage of everything.

4. Storage orientation. The saw can be transported or stored horizontally or vertically.

5. Carrying handle. The side handle for transporting is well placed, comfortably padded and balanced. Carrying this saw with one hand is very comfortable. It is easier to carry this larger DeWalt saw than it is to carry it's little brother the DeWalt DW745 which is a real hand-pincher to carry.

6. Tool-less removal of riving knife and guard.

7. Cord storage. I like that there is a place to wrap the cord out of the way for storage.

8. Dado blade capable. This saw will take up to a 13/16" dado blade stack according to spec.

9. Soft-start motor.

10. Steel roll-cage design. This eliminates a lot of the plastic of previous designs.

11. Dust port for a vacuum attachment on back of the saw (not to be confused with the dust port built into the blade gaurd mentioned below under things that could be improved.)

11. Price-point. Paid $499 at Lowes complete with the cross-buck stand. This saw has a lot of features for the $$.

Things that could be improved:

1. The place to wrap the cord should be moved over 1 or 2" to make more clearance for winding the cord. (I might just modify this myself)

2. Out-of-the-box accuracy. The owners manual states that the saw is set up accurately at the factory. The blade was 1/16" out of parallel to the miter slot, the fence needed to be adjusted for parallel and the bevel also needed to be adjusted. The adjustments were easy enough to make but the saw was not ready for use out of the box and it did take some time to get it adjusted.

3. Out-feed (or lack thereof). Attaching an out-feed table looks like it will be a challenge. I am going to attempt to build something today but I suspect that the rack-and-pinion fence mechanism is going to make it difficult. If I come up with something elegant I will post a photo of it. Wish me luck!

4. The fence is lightweight. It will be an adjustment to get used to after 20+ years using the bomber and reliable Rousseau fence. I hope that this fence holds up to job-site abuse.

5. Bevel adjustment. It would be great to have a separate wheel to adjust the bevel. Also, the adjustable cam stops for 0 and 45 degrees seem a bit awkward, under-built and unreliable. We'll see how they hold up.

6. Dust port on blade gaurd. Really? On top of the saw? For a job-site saw this is a real head-scratcher. I'm not sure how a vacuum hose will stay out of the way during a cut. I envision some dangerous hang-ups with the hose if it were to be used.

In summary, I am very happy that DeWalt has taken the best features of the DW744, DW745, and the Bosch GTS1031 and incorporated them into this one new saw.

5 of 6 people found the following review helpful.![]() Good for its intended purpose

Good for its intended purpose

By Sunfixer

This is a nice job-site saw. I have had it about two weeks and have been using it to cut laminate flooring and sub flooring.

There are other in-depth reviews here, but I have a couple of comments.

Attach & remove 4 nuts & bolts every time you want to attach/detach saw to stand - this is poor engineering! I am now using a clamp, much better!

The miter gauge included was a piece of junk. Wobbled in the track so much, you could never get an accurate cut. I replaced it with one I bought at Rockler Woodworking. It has an adjustable width feature that allows it to fit tightly in the track.

Overall, I am happy with my purchase.

1 of 1 people found the following review helpful.![]() 4 months and 21 drawers later: A very satisfied homeowner/carpenter

4 months and 21 drawers later: A very satisfied homeowner/carpenter

By K&J

Before I spend $500 on a tool I REALLY want to make sure it is up to the job. So for the like minded I offer the following detailed review: I've been doing homeowner carpentry all my life. But last summer I decided to finally tackle finish carpentry by building 21 custom sliding drawer/shelves for our kitchen's cabinets. I'd owned a Craftsman table saw but found that if the piece I was cutting got skewed, rather than cutting onward, the motor tended to partially stall and then recover by suddenly jerking the piece away from me. After one too many near accidents of this type, I gave the saw away. I'd also owned a radial saw which had power to spare but, when ripping, occasionally threw pieces of work across the room (sometimes propelling ME toward its all too exposed blade).

For cross cutting I'd found a safer/more-controllable alternative in a good compound miter saw. But I still needed a saw for ripping. From my earlier Craftsman experience I knew that a table saw needed lots of power (so that if the work DID get a bit skew, the blade would continue to plow on, rather than binding and/or throwing things). Hobbyist websites strongly recommended large heavy cast iron table saws. But they would have taken over most of my limited shop space, been essentially unmovable (as they weighed in at up to 1/4 ton) and cost well over a thousand dollars.

Reviews of this saw's predecessor model suggested it could do finish carpentry fairly well (with a much lower price, footprint, and weight). I decided to buy that model last September, right as it was discontinued. This newer saw had been announced, but via Amazon it was initially offered only from CPO at a full one hundred dollars over De Walt's $500 MSRP. I wasn't going to put up with that sort of banditry and thus instead bought it when it came to a local Lowes at list price. Four months have now passed. I have fabricated my 21 dovetail joined oak drawers with this saw and its companion DeWalt compound miter saw and router.

LIKES:

My favorite: On most table saws the fence is built sort of like a T-square with the fence making up the long backbone of the T and a much shorter crossbar clamping onto the front edge of the table. But, unless that cross bar clamps really tightly and accurately, the fence looses it alignment parallel to the blade. DeWalt instead uses a simple dual rack and pinion gear setup where a single fence adjustment knob turns a shaft running under the able which, at both ends, has pinion gears. These pinions drive racks on the front and back edges of the table to which the fence clamps (in several alternate positions). It is simple, lightweight, and when I ripped down my oak planks to make the drawer sides, the side widths matched perfectly. The indicator/ruler on cut width could also be aligned so well that it would give the true rip width as accurately as when I used a tape measure to measure blade to fence separation.

Smaller but still significant likes: It's light and easily moved around (even for an AARP cardholder). It has a big effective blade guard that is nevertheless easily removed by a spring loaded lever under the left edge of the table. It is relatively quiet (quieter than the shop vacuum I attach to its sawdust ports) and yet has enough power to avoid blade jamming. Its dual sawdust ports do capture 95% of the sawdust (but it sure would have been nice if DeWalt had included the hard-to-find necessary T adapter to merge these two ports to a single dust hose).

DISLIKES:

Just after I bought it I thought I had a lemon. Like every saw I have ever owned, you have to initially align the parallelism of the blade and fence. The manual shows you that the blade/motor/dust enclosure is a single assembly screwed to the underside of the table. You are told to loosen the two back screws attaching this unit to the table and to the then twist the assembly until the blade lines up parallel to the fence. I tried this (several times!) and hit the limit of the allowed twist before I could bring the blade into alignment. The only thing left was to find the remaining mounting screws holding the assembly nearer the front of the saw. These are much harder to find and reach, but I did so. But when I loosened them, I could get no further twist, leaving me with a blade still well out of parallel with the fence (with the fence well aligned to the table). However, as I was ready to send the saw back to DeWalt, I discovered that the reason loosening the front screws did not help was that when the miter lock was engaged it also locked the position of the blade assembly's front edge. So the trick was to loosen the miter clamp AND the front screws simultaneously. THEN I could finally get enough adjustment range to properly align the blade (which then stayed beautifully aligned throughout my drawer project. This more complete alignment procedure SHOULD have been detailed in the manual.

The manual did however, insist that if the saw was mounted on a solid surface that you cut a large rectangular hole in that surface to let sawdust escape. This made sense for the earlier model for which the base was fully enclosed. It is nonsense for this new model for which the base is not only open on three sides but for which the ports very effectively shoot sawdust not downward but to the back of the saw. The hole requirement was clearly a dumb carryover from the previous model's manual.

Finally, a nitpick: When connected to a shop vacuum, those dust ports DO capture 95% of the sawdust. The remaining 5% accumulates under the saw. This would be inconsequential on a jobsite. But it was still annoying for my in-home shop (particularly after I had laboriously tracked down the hose adaptors to connect to all of the dust ports). I figured out the problem: While the blade can be easily changed from above, DeWalt also allowed for changes from below by building in a side plastic cover to the blade motor assembly. The plate is mounted via tabs and slots at its bottom edge, allowing it to pivot closed and then engage two V-shaped spring locks. It works very easily - but it doesn't close tightly. However, I found that this plate also has two holes that line up with two 10-32 tapped screw holes in the assembly. No screws are supplied. But a pair of 3/4-1" 10-32 screws does a great job of clamping the plate and closing off the sawdust leak. (Clearly DeWalt spotted this shortcoming, engineered a solution, but then decided it wasn't worth acting upon).

To summarize, this saw IS capable of finish carpentry, and does so in a compact, easily movable and well-priced package.

No comments:

Post a Comment