Product Description

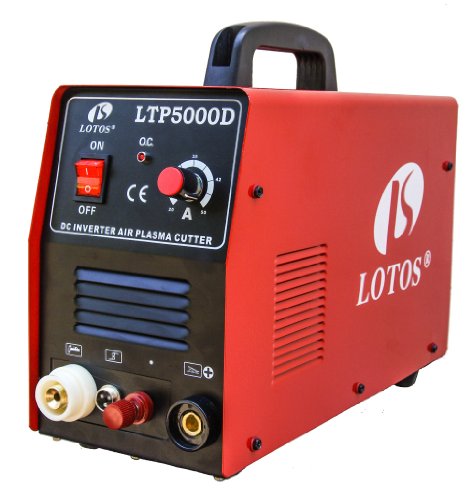

Lotos Technology is proud to offer an extensive selection of industrial plasma cutting machine, LTP5000D. Lotos LTP5000D is designed and constructed to withstand extensive use in rugged industrial and construction environments. It is perfect for any home project too.

Lotos LTP5000D is a 50A dual voltage 110/220vac Digital Inverter Pilot Arc Plasma Cutter (50A) with CNC cutting feature.

Lt5000d provides a better, cleaner cut. The torch trigger can be moved for a custom fit. It can be used in finger or thumb positions. Torch head is low profile for tight spaces. High Frequency DC Plasma cuts thicker materials than standard DC plasma cutters. High Frequency Plasma cuts faster with less distortion in the work piece.

What is the difference between the Lotos LTP5000D and the Lotos LT5000D (or Cut50D)? The Lotos LTP5000D uses the IGBT technology which is more reliable and robust than Mosfet technology present in the LT5000D. Also, the LTP5000D is a pilot arc plasma cutter which is a good feature for customers who need to cut rusty material (In a pilot arc torch, when you press the trigger of the torch, the machine will automatically strike an arc, you don't need to remove the rust before cutting. For contact arc cutters, like the LT5000D, all the rust must be cleaned off in order to cut the rusty material. In addition, in cases where the torch cannot touch the metal, such as the corner piece of a metal frame, you will need to use a pilot arc cutter as a contact arc (asthe name implies) requires contact. 90% of all our business customers have purchased the LTP5000D over the LT5000D.

Product Details

- Amazon Sales Rank: #7544 in Home Improvement

- Brand: Lotos

- Model: N102

Features

- Automatic Dual Voltage / Dual Frequency (110/220V 50/60Hz) (you need an 110 or 220vac power plug)

- Robust Infineon IGBT By Siemens, Germany

- Max Severance Thickness: 3/4" 60% duty cycle

- Integrated Pilot Arc Function, Both Contact and Pilot arc starts.

Customer Reviews

Most helpful customer reviews

18 of 19 people found the following review helpful.![]() So glad I bought it!

So glad I bought it!

By C.Shar

Excellent Plasma Cutter, especially for the price. Restoring a Jeep with a bunch of cancer spots. I was considering a plasma cutter primarily to cut out the rust and cutting sheet metal to fill. I've used it for that and so much more. This little beast cuts through 16 guage sheet metal like a knife through butter, and cut 1/4 sheet metal without any hesitation. Cuts were nice and clean with very little slag. It slices through 7/16 bolts like their nothing.

Much smaller than I expected. I've borrowed a friends older Hobart Plasma Cutter, but this Lotos is half the size and significanlty outperforms his. I can't imagine how many cutting disks I would've gone through or how many hours I would've expended to get to achieve the same results I've gotten in a fraction of the time.

15 of 16 people found the following review helpful.![]() No comprehensive instructions or parts list - surprised by cutting ability

No comprehensive instructions or parts list - surprised by cutting ability

By AEinstein

There are no -comprehensive- instructions or parts list included with the plasma cutter and there doesn't appear to be -any- parts or installation or user manuals online or available from the manufacturer.

POWER REQUIREMENT:

Although this -can- be used on 110-120v circuits I would not even try.

REASON- the unit (according to the plate) has a power factor of .93 and rated at 6.3KVA which makes it 5.859KVA used power. If you connect this to a 110-120v outlet it would require at least 52 AMPS, respectively. That would probably take 8ga wire. A 220-240v connection would half the amps and use 12ga wire.

-----

I -finally- received a working cutter (first one was damaged due to improper packaging).

-This is the first plasma cutter I have owned or used-

WHAT YOU NEED TO BUY & SETUP:

You need a power plug for your connection.

This cutter comes with an air regulator and short hose to connect the regulator to the unit.

You will need to purchase a piece of hose, hose clamps, and a connector to attach the regulator to your air compressor.

Also, if you do not already have welding equipment you will need a helmet, gloves, Etc.

The air hose connections need to be -tightly- connected with the provided hose clamps being careful to make sure the clamps are over the -barbs-, otherwise they will leak air.

USING THE CUTTER:

There is a wire looking piece that clips on the end of the cutter and is not mentioned in any of the sparse instructions. This is -apparently- meant to keep the cutter at a distance from the part being cut.

After connecting your compressor, just set the pressure regulator, hook up the ground to the metal you are cutting, and turn it on.

To start you just push the button on the cutter while near the metal.

RESULTS:

After getting all the hose (and power) connections and hooking everything up I tried cutting some metal.

I was blown away by the ability of the cutting 'plasma'.

It slices through metal like butter! The surrounding metal doesn't seem to get very hot. The 'plasma' stream just 'washes away' the metal it is cutting.

I don't know how thick a metal it will cut, but from the power settings I used on the size metal I was cutting I would say 1/2 inch should be easy.

This plasma cutter will save anyone a lot of hack-sawing or any other metal cutting time.

11 of 11 people found the following review helpful.![]() Excellent cutter for a great price

Excellent cutter for a great price

By 40OldsBV

Having read earlier reviews, I knew not to expect a lot of technical info with the plasma cutter, so I went to YouTube and watched a couple of videos from makers of much more expensive machines before I even opened the box. Sure enough, these plasma cutters are all very similar, so assembling and using the LTP5000D was easy. The torch parts look slightly different among cutters, but are basically put together in the same order and do the same functions. I set mine up for 220V and have a 5HP air compressor, so cutting 1/4" steel is no problem at 35 amps on the front controller. So far I've cut stuff ranging from 22 gauge sheet metal (fenders) to car frame parts. I even hogged off a large chunk of heavy, very rusty galvanized pipe. The videos will show how to start the cuts (including plunge cuts) and keep the arc going. A little practice and you'll be going like gangbusters. A couple of things to know. The air hose provided with the kit is too hard to seal, replace it with a piece of rubber air hose and good clamps. Use lots of teflon tape on the air regulator input and output connectors. Set the air pressure out at 70 psi. The torch trigger is not guarded and is black, so it is easy to bump (especially with your welding helment on). This is a pilot arc cutter, so it will spark at any time the power is on and you hit the trigger. The price is right on this cutter for the average home user (about half the price of the name brands).

No comments:

Post a Comment